Alle unsere Spezialisten haben die gleiche Denkweise: Wir denken wie die Automobilindustrie. Wir lieben, was wir tun – ganz gleich, ob wir uns mit Beleuchtungssystemen, elektronischen Systemen oder mit Testsystemen beschäftigen. Wir sind der festen Überzeugung, dass die Vorbereitung auf die Zukunft Verständnis, technisches Know-how, den Einsatz geeigneter Werkzeuge und Prozesse sowie Testmöglichkeiten erfordert und zwar alles auf der Ebene der Systeme.

LEISTUNGEN

BELEUCHTUNG

TESTING

E/E

LEISTUNGEN

BELEUCHTUNG

TESTING

E/E

Alle unsere Spezialisten haben die gleiche Denkweise: Wir denken wie die Automobilindustrie. Wir lieben, was wir tun – ganz gleich, ob wir uns mit Beleuchtungssystemen, elektronischen Systemen oder mit Testsystemen beschäftigen. Wir sind der festen Überzeugung, dass die Vorbereitung auf die Zukunft Verständnis, technisches Know-how, den Einsatz geeigneter Werkzeuge und Prozesse sowie Testmöglichkeiten erfordert und zwar alles auf der Ebene der Systeme.

KNOW HOW

Wir sind das Engineering-Service-Team, das unseren Kunden den entscheidenden Vorsprung verschafft – mit Kreativität und Know-how in allen Phasen des Produktentwicklungsprozesses. Arbeite zügig, sei kosteneffizient und liefere einen Mehrwert.

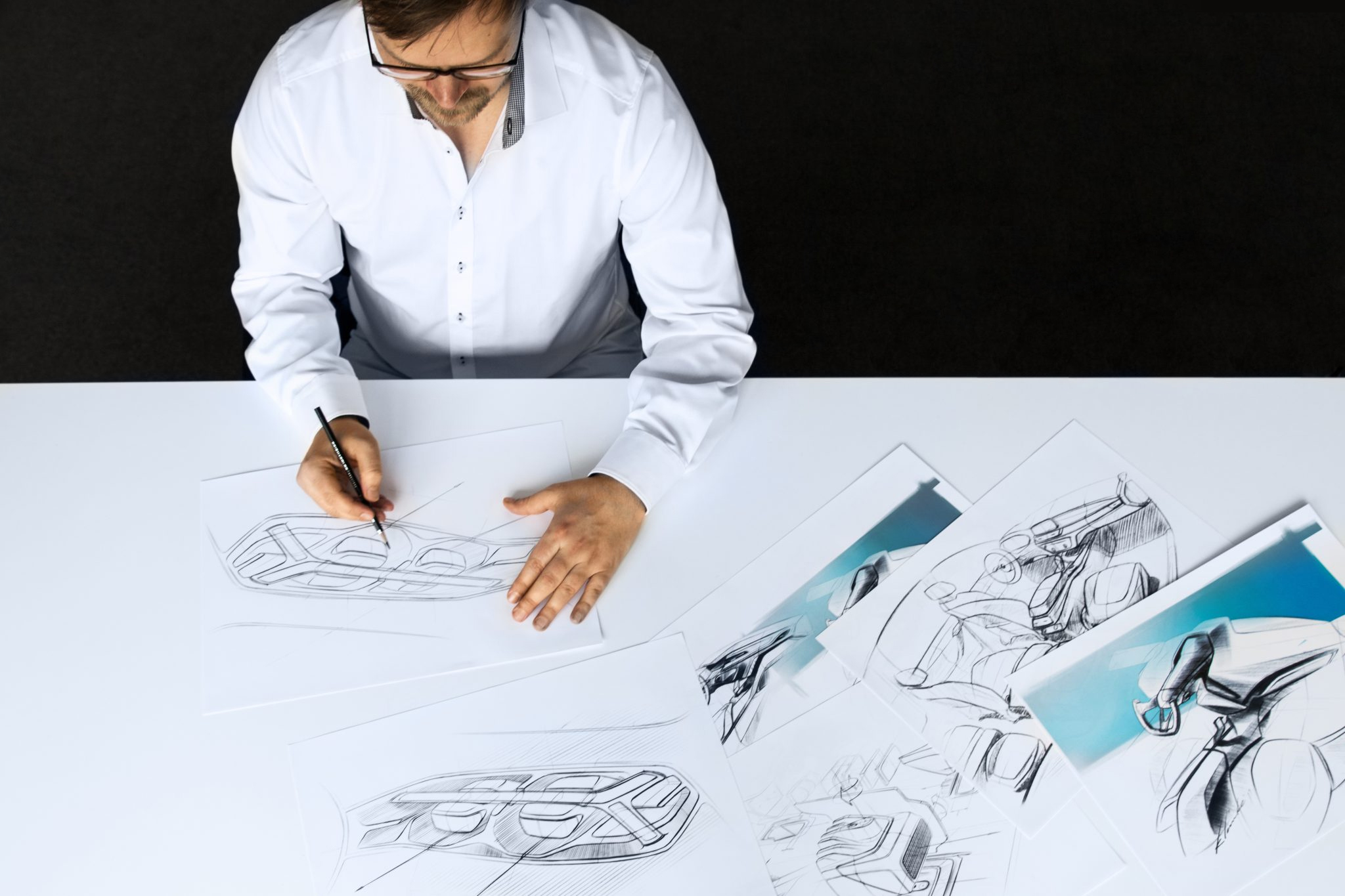

Design & Styling

- Skizzieren

- Visualisierung (PHOTOSHOP)

- Rendering (KEYSHOT, VRED, MAXWELL)

- Class A-Flächenmodellierung (ICEM, ALIAS)

- Parametrisches Design mit Grasshopper

- Trendscouting

Maschinenbau

- 2D-/3D-Modellierung (CATIA)

- Toleranzanalyse

- Design to Cost

- Design for Manufacturability/Assembly

- BOM

Optische Konstruktion

Nicht-bildgebende Systeme

- Facettenreflektoren (LUCIDSHAPE)

- Lichtleiter (SPEOS + hauseigene Software)

- Refraktive optische Elemente / Fresnel-Linsen

Bildgebende Systeme

- Einzelfunktions-/Multifunktionssysteme

- Miniaturisierte Projektorsysteme

- Mikro-Linsen-Array-Systeme

- Hochauflösende Bildgebung

Tolerancing

Elektronik-Hardware

- Schaltbilder

- Leiterplattenaufbau (MCPCB/FR4/FLEX)

- Simulation

- Bussysteme (LIN/CAN/LAN)

- Mikrocontroller

- Treiber-Topologien (Buck/Boost/Buck-Boost)

- Fehlererkennung

- EMV-/EMI-Optimierung

Elektronik-Software

- Firmware

- Integration von Standardkomponenten (Bootloader, LIN/CAN, …)

- Diagnose-Funktionalität

- Funktionssicherheit

- ASIL-Level A+B

- Entwicklung von Algorithmen

Thermische Konstruktion

- Konstruktion auf Leiterplatten-/Komponentenebene

- Optimierung auf Systemebene

- Kondensation/Antibeschlag

- Berechnung der Sonneneinstrahlung

- Statische und transiente Simulation (Flo-EFD)

Projektmanagement

- Beschreibung auf Komponenten- und Systemebene

- Anforderungsmanagement

- Zeit-/Kosten-/Qualitätsverfolgung

- Änderungsmanagement

Validierung/Prüfung

- Prototypentwicklung: Dummys, ästhetische Muster, Funktionsmuster

Vorbereitung von Prüfmustern und -geräten - Optik-Labor: Spektrometer, Ev-/Iv-/Lv-Meter, Goniometer

- Elektronik-Labor: Funktionsgenerator, Oszilloskop, Micro-Auto-Box, automatisiertes Prüfsystem, VECTOR VT-System, EMV

- Thermo-Labor: Thermoelemente mit Schreibersystem, IR-Kamera

- Umweltlabor: Klimakammer, Korrosion, Vibration

LEISTUNGEN

Forschung + Technologie

Aktivitäten zu Beginn des Produktentstehungsprozesses, um Styling- und Technologietrends zu erkennen und diese in kommenden Fahrzeugen zu nutzen.

- Styling und Technologie-Trendscouting

- „Ideen“-Workshops

- Funktionsmuster

- Fahrzeugintegration

- Benchmarking

- Unterstützung der Produktdefinition und der Produkt-Roadmap

Vorentwicklung

Festlegung der Grundlage für ein spezifisches Produkt durch Definition der ästhetischen und technischen Rahmenbedingungen und Schnittstellen.

- Class-A-Modellierung und Visualisierung/Rendering

- Verifizierung der technischen Machbarkeit und Feedback an Design

- Rechtliche Prüfungen / Homologationsfähigkeit

- Beschreibungen auf Komponenten- und Systemebene

- Spezifikationserstellung

RFQ-Phase

Die Kernaufgabe ist die Ausarbeitung von technischen Konzepten und deren Durchführbarkeit aus technischer, fertigungstechnischer und wirtschaftlicher Sicht.

Auf OEM-Seite:

- Technische Abklärung mit potenziellen Lieferanten

Auf TIER-1/2-Seite:

- Spezifikationsbewertung / Anforderungsmanagement

- Technisches Konzept und Umsetzbarkeit

- Montage-/Fertigungskonzept

- BOM

Produktentwicklung

Die Produktentwicklung folgt in der Regel dem V-Modell-Ansatz für Spezifikation, Entwicklung und Prüfung, um eine nahtlose Übertragung an die Produktionsentwicklung zu ermöglichen.

- Auf OEM-Seite:

- Projektmanagement / Komponentenverantwortung

- Schnittstelle zwischen den technischen Abteilungen von Tier 1 und OEM

- Auf TIER 1/2-Seite (teilweise oder in voller Projektverantwortung):

- Design to Cost / Design for Manufacturability / Tolerancing

- Prototypenerstellung in verschiedenen Qualitäten nach Bedarf in der aktuellen Projektphase

- Prüfung und Verifizierung auf Komponenten- und Systemebene

Werkzeuge + Ausrüstung

Einrichten und Optimieren der Produktionsausrüstung und der damit verbundenen Prozesse entsprechend den Produktanforderungen.

- Auf OEM-Seite:

- Projektmanagement / Komponentenverantwortung

- Schnittstelle zwischen den technischen Abteilungen von Tier 1 und OEM

- Auf TIER-1/2-Seite:

- Unterstützung bei der Überwachung der Ausrüstung und der Werkzeugoptimierung

- Technische Unterstützung bei der Werkzeugoptimierung

Qualifikation + Homologation

Produktverifizierungsprüfungen und damit verbundene Aktivitäten zur Vorbereitung der Produktionsfreigabe.

- Auf OEM-Seite:

- Projektmanagement / Komponentenverantwortung

- Schnittstelle zwischen den technischen Abteilungen von Tier 1 und OEM

- Auf TIER-1/2-Seite:

- Überwachung und Fehlerbehebung

- Unterstützung bei der Optimierung von Produktionsprozessen

- Vorbereitung, Überwachung und Beurteilung der Qualifizierung und Homologation

Produktionsanlauf

Überwindung unerwarteter Situationen während des Anlaufs, um eine profitable Produktion zu erreichen.

-

- Projektmanagement / Komponentenverantwortung

- Überwachung und Fehlerbehebung bei Qualitätsproblemen und Lieferengpässen

- Schnittstelle zwischen den technischen Abteilungen von Tier 1 und OEM

- Auf TIER-1/2-Seite:Auf OEM-Seite:

- Unterstützung bei der Analyse von Fehlerursachen und Überwachung von Abhilfemaßnahmen